Best Times Mould & Plastic Products Technology Ltd., A professional China plastic injection mould manufacturer who specializes in plastic injection mould manufacturing and plastic injection molding with 15 years experience.

Found

2007

Square Meters Area

6500+

Employees

130+

Designers & Engineers

20

Mold Technicians

45

Sets Molds Per Year

400+

Any new projects for a competitive quote?

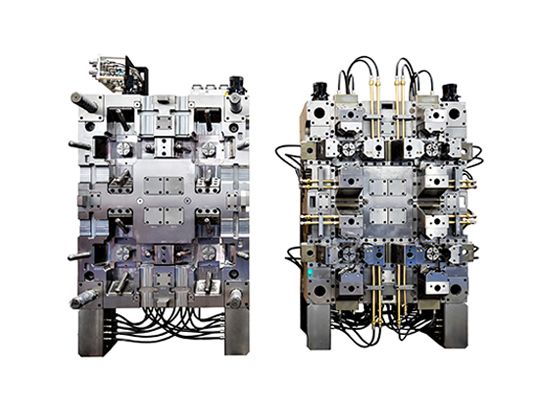

Request A QuoteBest Times Mould & Plastic Products Technology Ltd. covers a 6500 square meters factory with 130 staff. We have a professional engineering & manufacturing team with extensive experience in mould manufacturing and plastic injection molding field. We are equipped with precision CNC machining center, EDM, Mirror EDM,Wire EDM,Milling machine, Grinding machine to manufacturing high precision mould to meet our customers' requirements on cost, high quality, fast lead-time.

Best Times Mould & Plastic are also equipped with advanced plastic injection moulding machines from 60 Ton to 2500 Ton clamping force, including multi-shot injection molding machine for 2-shot & 3- shot injection molding.

Are you interested in a customized solution for your new project?

Request A QuoteCustomized Process(OEM & ODM)

Product design Prototype

DFM report

(Mold flow analysis)

2D Mould Design

3D Mould Design

Mould manufacturing

Mould trial/sampling

Samples

inspection/ approval

Mould

inspection/ approval

Mould export

Parts production (non export mould)

Package & Shipment

After-sales Service

Why Choose Us

Professional engineering & business team

We have a professional engineering team and business team, most of them have more than 10 years experience in mold-making industry and injection molding industry, especially for medical, electronics and automotive products.Our team include 10 mold designer, 2 quote engineer, 5 project engineer, 3 Q.C engineers, 8 sales specialists team with multi-languages capability to service our customers from USA, Canada, Germany, France, UK, Spain, etc.

Advanced Equipment

We have advanced equipment including High speed CNC center (4-axis and 5-axis CNC machines), Mirror EDM, W-EDM from HAAS, MOKRON, OKUMA, AGIE, MAKINO, so that can meet your high precision mould requirement. We also have 87 plastic injection molding machine from 60~2500 Ton clamping force, we have six sets two-shots injection molding machine for two-shots molding (120T,200T, 250T).

All process project management

Easy communication: All sales & project engineers can speak English fluently. Rich experience: Our team is familiar with various export mold standard such as: DME, HASCO, MISUMI, MEUSBURGER, LKM etc. Real-time control: Progress report in every week with Gantt chart & photos. Full project management system: Detailed project procedure for every step from beginning to end: DFM & MF review, 2D&3D mold design, weekly progress report, FAI report, etc.

Factory price, Fast free quote

We provide competitive factory price by strict cost control & advanced manufacturing process. We can help you save 10%~30% manufacturing cost compared with others suppliers. We have two quote engineers with over 15 years of industry experience to provide free competitive quote within 24 hours, DFM report offered if needed before your new project kick-off. We can help you study and recommend the material (mould steel and plastic resin material).

One-stop service, fast lead time

We offer one-stop service from products design and prototype/samples make, Mold design & manufacturing, plastic injection molding, secondary operation & assembly package, delivery to your warehouse & office with fast lead time. Our experienced strong team take care of your project from idea to high quality real product with smooth communication on every step & process so that you can have your idea realized with shortest time easily & confidently.

Strict Quality Control

Best Times Mould & Plastic has independent quality control department to control every quality inspection step from incoming material, production process, assembly, packing, as well as cargo shipment. We have established quality evaluation program for each process to assure best quality and most professional service to our customers. We carry out full inspection reports like monthly/seasonal/yearly quality analysis report, CPK, FAI, IQ, OQ, PC, PPAP, PFMEA etc.

PLASTIC INJECTION MOULDS

> HASCO, DME, MISUMI, MEUSBURGE,LKM,etc. Standard

> 1.2344, 1.2343, S136, NAK 80,738,718,P20,etc. Mould steel

> Yudo, Incoe, Mold-Masters,Synventive,Husky, etc. Hot runner

> Free Trial samples for your approval before shipment

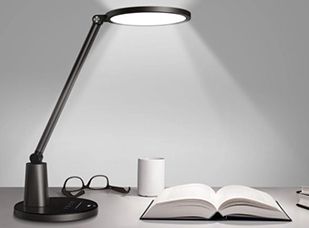

PLASTIC INJECTION MOULDED PARTS

> ABS/ PC/ PVC/ PP/ PET/ PMMA/ POM/ PS/ TPE/ TPU/ ASA, PSSU/ PEEK, etc plastic resin

> Pantone/ RAL colors,or customized colors

> SPI/ VDI/ Logo imprinting/ Painting/ Electroplating, Oil spraying, etc surface finishing

> Free Trial samples for your approval before mass production

Our Partner & Suppliers

Our Customers

MARKETS WE SERVE

We are trusted by many clients from USA,Canada,Germany,France,Spain,Poland,Czech. They are satisfied with our services and value our expertise and experience. We are always improving to enhance our capabilities to exceed our customers' expectation.We are here to meet your customized needs (new project & product).

Need a competitive price & quote for your new projects & products ?

Request A QuoteMar. 01, 2022

How to choose & determine plastic resin materials for your plastic molding product project?

Read MoreQ:What information do you need for quotation? How fast does it take to quote a project?

We need 2D and/or 3D part drawing, and specific mold or part requirements.(requirements on mold steel, mold life, cavity quantity, hot runner brand if you need, part material, estimated annual quantity. )More detailed information will help a faster accurate quote. 2D File Format dwg /dxf /pdf/jpg , 3D Model Format step /x_t /igs /prt. Normally it take 1~2 working days to quote a new mold project seriously.

Q:Could you quote by sample or photo & sketch?

It is no problem. We can prove a rough price for your information according to sample or photo & sketch. An accurate price needs you provide more information if you have.

Q:What’s the price terms/freight Best Times Mould will offer?

Normally Best Times Mould will offer ex-work factory price for injection mold and plastic parts. We also provide FOB, CIF, DDU, DDP (door to door) price terms as per customers requirement. We can ship the mold and parts by sea, by air and by international express (FedEx, UPS, DHL, TNT, etc. ) Free mold trial samples free of charge and with freight to collect. VIP customer special terms: to be negotiated.

Q:How about the tolerance you can meet? What is the max weight & size of molds you can make?

Mold tolerance is 0.01 mm, Product tolerance is 0.025mm.

We can make large molds up to 10 tons weight, max size up to 1.8 Meter.

Q:What steel do you usually use?

We usually use steel of P20, H-13, S-7, 420, 420SS, NAK80, 1.2311, 1.2738, 1.2343/1.2344, 1.2083, 1.2316,

S136, 718H, 718, 8407, etc.Mould Steel suppliers: LKM; ASSAB; THYSSEN; DAIDO; FINKL and Gröditzer, etc. Steel certificate and heat-treatment certificate will be provided along with the tools while delivery if required.

Q:What standard components do you usually use?

We use standard components from HASCO, DME, LKM, MISUMI, MEUSBURGER, etc.

Mold base suppliers: LKM, FUTABA, HASCO, DME, etc.

Standard components suppliers: HASCO; DME; LKM; MISUMI; CUMSA; MEUSBURGER etc.

Hydraulic cylinder suppliers: HPS; PARKER; VEGA and MERKLE etc.

Texture suppliers: Mold-Tech, YICK SANG, etc.

Q:Could you make hot runner mould?

Yes, We can make hot runner moulds with hot runner brands: MOLD-MASTER, HUSKY, DME, HASCO, INCOE, THERMOPLAY, SYNVENTIVE, HRS, EWIKON, GUENTHER, YUDO, etc.