There are many types of injection mold and tooling in using today, such as two-plate, three-plate and stack molds. Two and three- plate molds are more commonly used for heavy wall and non-packaging products. Both cold and hot-runner systems are used for two and three plate molds. All stack molds use a hot manifold to convey the melt to the cavities. Each mold component must be machined and finished to exact dimensions with very tight tolerances and must be heat-treated to be able to withstand very high injection and clamp pressures. Injection molds are the most expensive molds used in plastics processing with very long lead times, required for their design and fabrication. Every injection mold must be tested and debugged to prove-out the ejection system, cooling and/or heating system and operating components before it is placed in production.

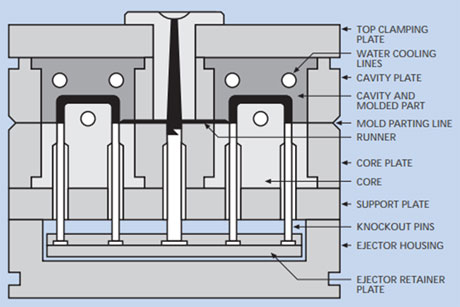

Two-plate injection mold has only one parting line. If a runner is used, it is connected to the molded product and requires manual removal and separation after the part is ejected. This type of injection mold is the least expensive to make and is commonly used for parts with relatively simple geometries.

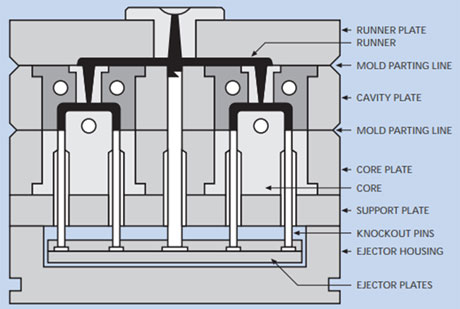

Three-plate injection mold has two parting lines, one for the runner system and one for the molded product. When the injection mold opens, the runner is automatically separated from the product to allow separate handling. This eliminates the need for manual separation and removal and the sprue and runner system may be fed directly to a recycling system. This type of mold is more expensive than the two-plate mold.

Stack injection mold can be two, three or four levels. The advantage of the stack mold is that it can, generally, produce a larger number of products versus a two or three-plate mold utilizing the same machine clamp tonnage. The disadvantage is that it requires a molding press with much greater daylight opening to accommodate the mold height. This type of injection mold is much more expensive and takes longer to build. Three level stack molds are very new and four level stack molds have been around for less than five years. The dairy container and lid industries commonly use stack molds. The four-level is common for lids, and the two-level is common for containers.